What is CNC Milling?

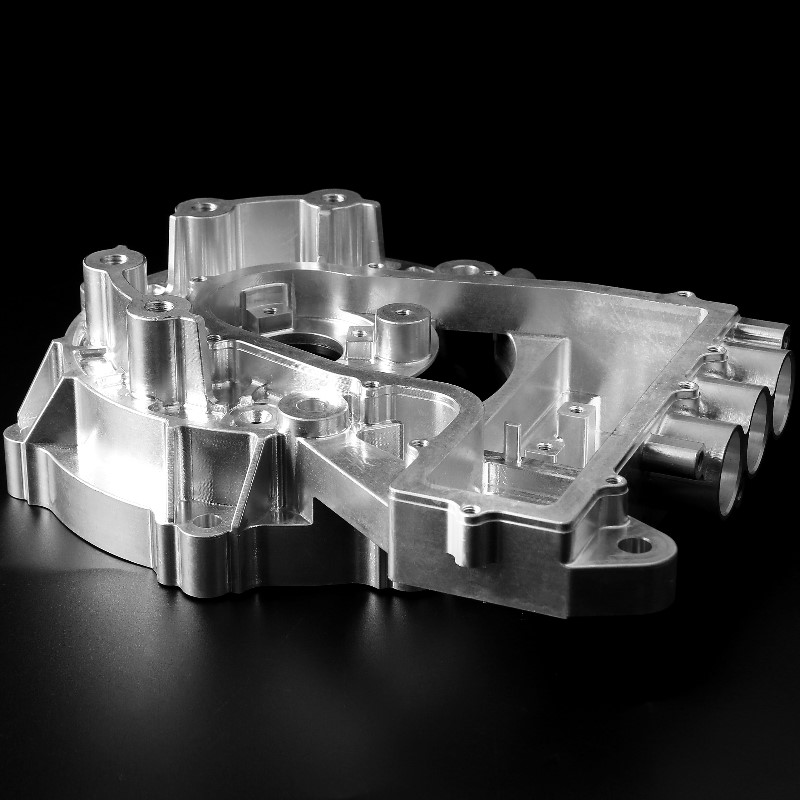

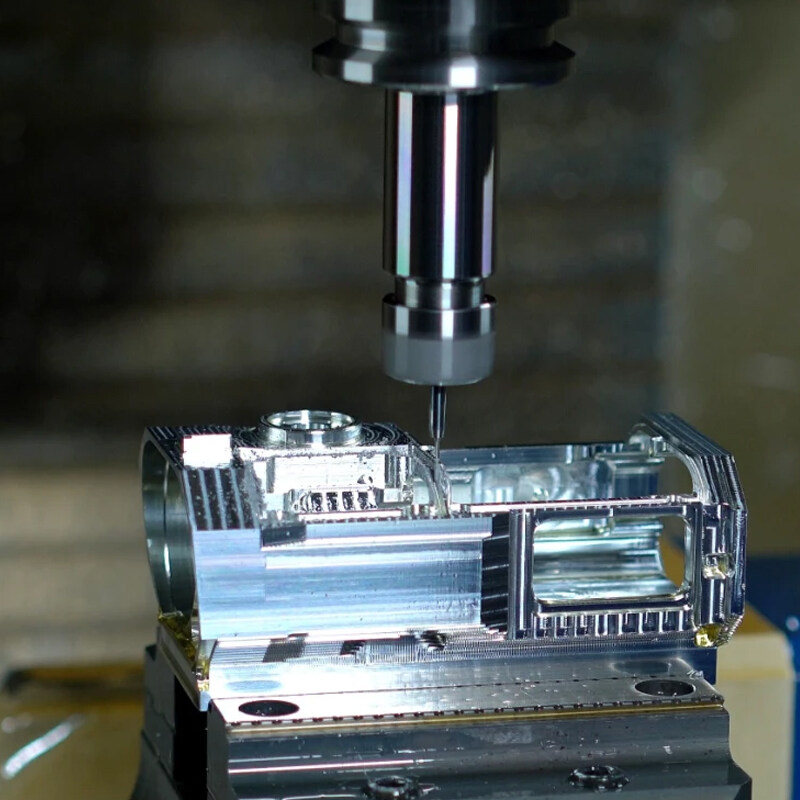

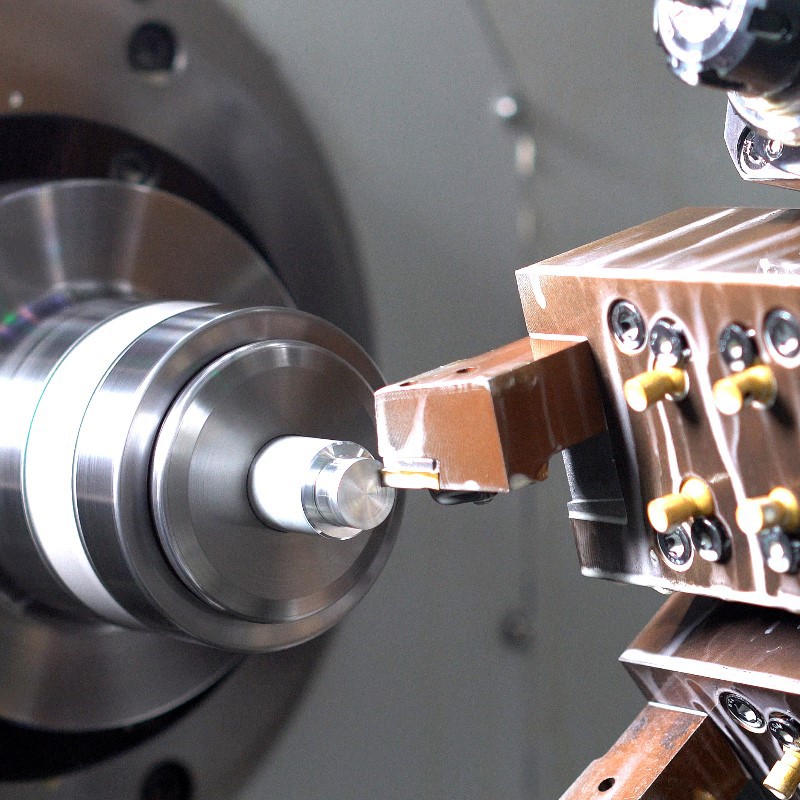

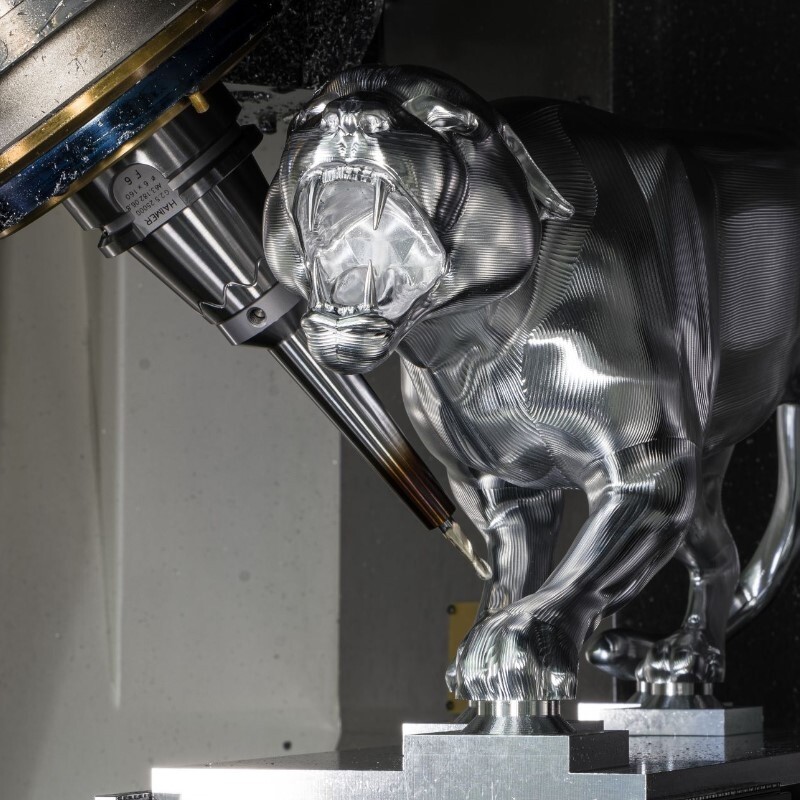

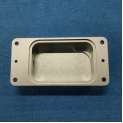

Milling is the process of removing material from a solid blank to create a finished or semi-finished shape. The process is guided by your CAD file, optimized to create a physical copy of your digital design.

In CNC milling, the workpiece is held in a rigid vice or holding fixture, mounted on a work table. This table rotates as well as pivots, making two axes of movement. Cutting tools mounted on a rotating spindle remove material to create a variety of complex geometries and part features on the workpiece. The real advantage of a multi-axis milling machine, such as our Haas UMC-750 milling center, is that the worktable and the spindle move on many axes independent to one another, providing not only accuracy and repeatability but also versatility.

From 3-axis basics to intricate 5-axis projects, our precision CNC milling makes your designs come alive with unmatched accuracy and craftsmanship.

CNC Milling Tolerances

Future Parts ensures precision with our CNC Milling Tolerance standards. We commit to exact measurements, benefiting clients with consistent, high-quality results, optimized for search visibility. Our standard tolerances for CNC milled metals are ISO 2768-m and ISO 2768-c for plastics.

| Type |

Tolerance |

| Linear dimension |

+/- 0.025 mm

+/- 0.001 inch |

| Hole diameters (not reamed) |

+/- 0.025 mm

+/- 0.001 inch |

| Shaft diameters |

+/- 0.025 mm

+/- 0.001 inch |

| Part size limit |

950*550*480mm

37.0* 21.5 * 18.5 inch |

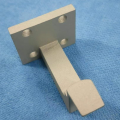

The Feature of product

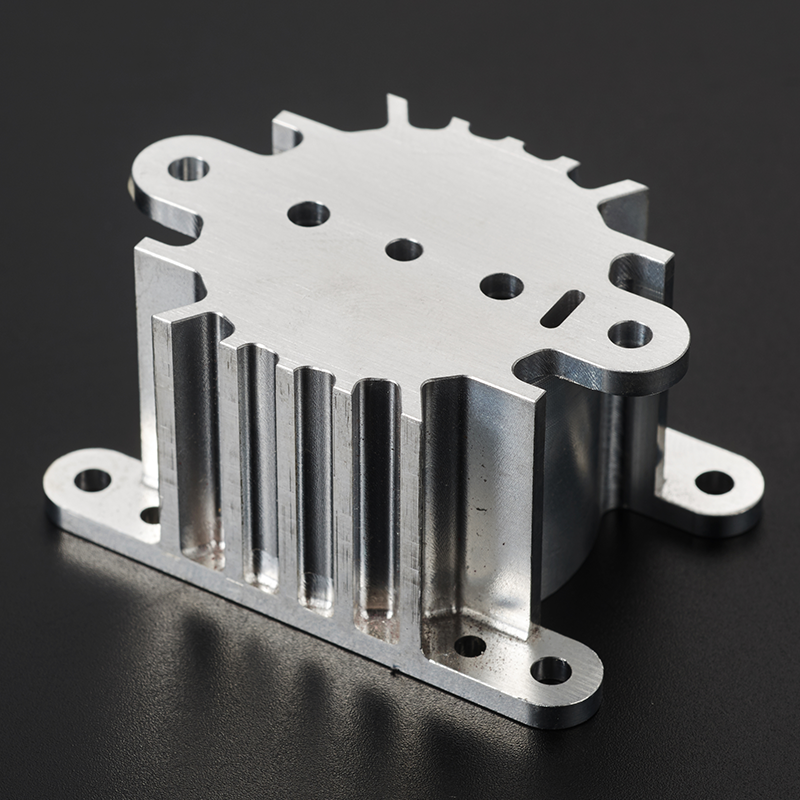

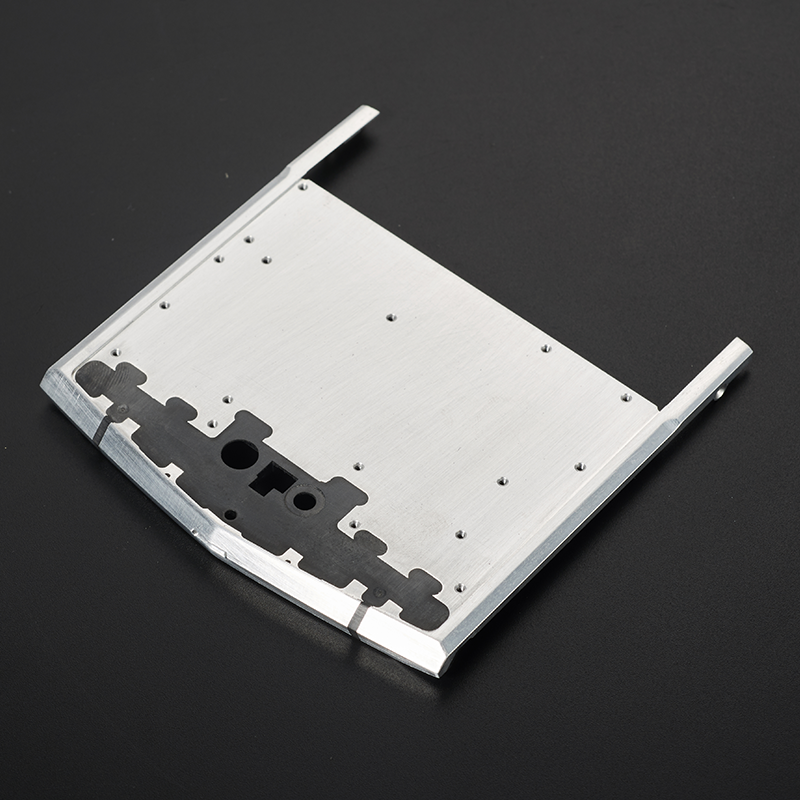

- CNC milling is ideal for making angled shapes, slots and channels, chamfers, holes, curves and flat surfaces, among many other features. A CNC mill removes large amounts of material fast with high accuracy, while producing a good surface finish. Milling can be done on any rigid material, though we primarily work with metals and plastics. Of all available CNC machining processes, milling is the most versatile.

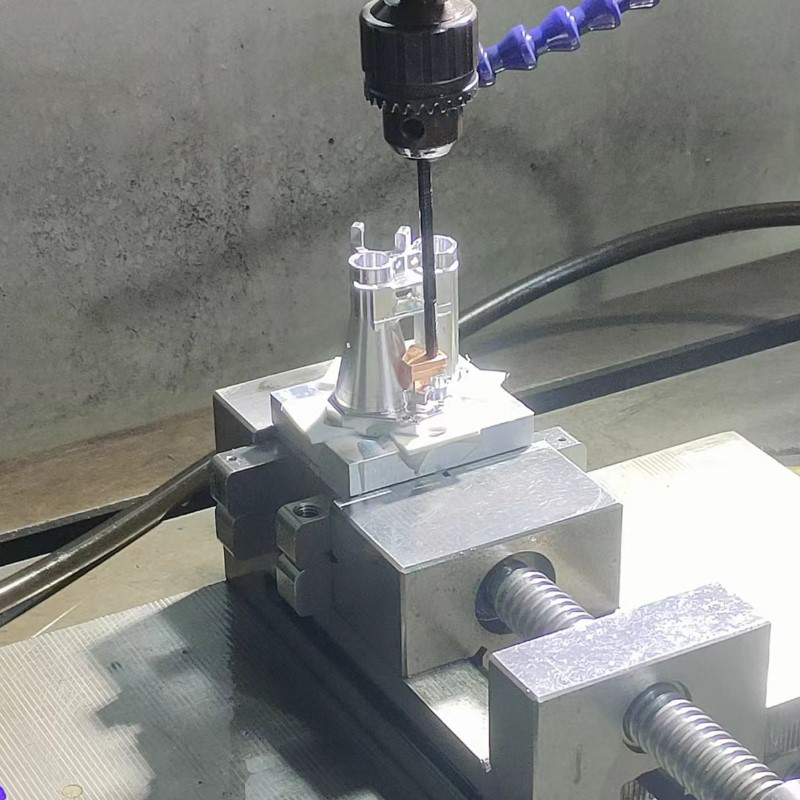

- Milling is used not only to make finished parts but also to build tooling for plastic injection molding and pressure die casting. Set-up time is minimal, so a CAD file can be translated into a finished part in a matter of hours. Because there is no need to make other specialty tools, you aren’t committed to a minimum order quantity so the process is very cost effective with little waste.

The Application of product

Specialized in crafting complex finished parts and components with high precision.

Capable of producing tools for plastic injection molding or pressure die casting.

- Secondary Operations with CNC Manufacturing:

Utilized for secondary operations such as drilling, tapping, and milling on machined parts.

Applicable to parts produced through various manufacturing processes.

- Versatility of CNC Mills:

CNC mills are the most common and versatile multi-axis machines employed at Future Parts.

Come in various specialized types to perform a wide range of operations on raw stock.

- Materials for CNC Milling Parts

Our CNC milling processes are compatible with a wide range of materials, including machine-grade metals and plastics. Depending on your applications, we can create precise rapid prototypes and low-volume production from various superior-quality materials.

Common materials including: aluminum, copper, brass, stainless steel, titanium, plastic(POM,PEEK,HDPE,PET,Nylon,PITE, PVC, PP, ABS, PC, PMMA),etc.

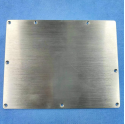

- Surface Finishes for CNC Milling

Gain access to quality surface finishing for custom CNC milled parts to remove aesthetic flaws and improve the appearance of your products. We also provide rigid protection and additional resistance and strength to your parts through superior surface finishes.

Choose the right surface treatment based on your needs. Enhance material appearance and performance with customizable colors and textures.

| |

Name

|

|

Materials

|

Color

|

Texture

|

|

Anodizing

|

Anodizing improves corrosion

resistance, enhancing wear

resistance and hardness, and

protecting the metal surface.

Widely used in mechanical parts,

aircraft, and automobile parts,

precision instruments, etc.

|

Al uminum |

Clear, black, grey,

red, blue, gold.

|

Smooth,

matte finish.

|

|

Bead Blasting

|

Bead blasting results in parts

with a smooth surface with a matte

texture. Used mainly for visual

applications and can be followed

by other surface treatments.

|

ABS, Aluminum,

Brass, Stainless

Steel, Steel

|

N/A |

Matte

|

|

Powder Coating

|

Powder coating is a type of

coating that is applied as a free-

f lowing, dry powder. Unli ke

conventional liquid paint which is

delivered via an evaporat ing

solvent, powder coating is

|t ypically applied

e lectrostatically and then cured

under heat or with ultraviolet

1 ight.

|

Aluminum,

Stainless Steel,

Steel

|

Black, any RAL code

or Pantone number

|

Gloss or

semi-gloss

|

|

Electroplating

|

Electroplating can be functional,

decorative or corrosion-related.

Many industries use the process,

including the automotive sector,

in which chrome-plating of steel

automobile parts is common.

|

Aluminum, steel,

stainless steel

|

N/A |

Smooth, glossy

finish

|

|

Polishing

|

Polishing is the process of

creating a smooth and shiny

surface, either through physical

rubbing of the part or by chemical

interference. The process produces

a surface with significant

specular reflection, but in some

materials can reduce diffuse

reflection.

|

Aluminum, Brass,

Stainless Steel,

Steel

|

N/A |

Glossy

|

|

Brushing

|

Brushing is a surface treatment

process in which abrasive belts

are used to draw traces on the

surface of a material, usually for

aesthetic purposes.

|

ABS, Aluminum,

Brass, Stainless

Steel, Steel

|

N/A |

Satin

|

|

Painting

|

Painting involves spraying a layer of paint onto the surface of the part. Colors can be matched to a Pantone color number of the customer’s choosing, while finishes range from matte to gloss to metallic.

|

Aluminum, Stainless Steel, Steel

|

Custom |

Gloss,

semi-gloss, flat, metallic, textured

|

|

Alodine

|

Chromate conversion coating, more commonly known by its brand name Alodine, is a chemical coating that passivates and protects aluminum from corrosion. It is also used as a base layer before priming and painting parts.

|

Aluminum

|

Clear, Gold |

Same as before

|

|

Part Marking

|

Part marking is a cost-effective way to add logos or custom lettering to your designs and is often used for custom part tagging during full-scale production.

|

All materials

|

Custom |

N/A

|